Accessory V series: MK-105A.MK-106A

- Home

- Products

- Fine Spot Welders

- Weld Head/Checker and Tester

- Checker and Tester

- MK105A.MK-106A

V series force follow-up mechanism

Stable weld force is applied in accordance with the thermal expansion and contraction of the weld joint since force is adjusted by a spring. There is a strong lineup of force follow-up mechanisms compatible with various micro-spot welding methods, which can supply high-equality welding for a wide variety of components to be joined.

Furthermore, models equipped with displacement and force sensors have been added to the lineup in order to meet the quality control needs.

- ◆VP model

Designed for direct welding, the most common application. Passes electric currents directly through the parts via one axis. Also available is the SS type for micro-force application (max. 700g).

- ◆VB model

This two-axis type allows you to set a uniform force for both the two axes thanks to the balance mechanism. Can be used for series welding of parts with a uniform thickness and a form that inhibits direct welding (can also be used for indirect welding).

- ◆VT model

This two-axis type allows you to set a different force for each of the axes. Can be used for indirect welding performed when parts with significantly varying thicknesses are welded and when power can be supplied only on one of the axes (can also be used for series welding). Furthermore, the SS type for micro-force application (max. 700g) can be used for parallel gap welding.

- ◆Twin-shaft model focusing on durability!

- ◆Model equipped with a displacement sensor (VPD, VTD, and VBD series)

- More rugged construction compared with the conventional models. Anti-rotation bearing system.

- The low inertia design that is ideal for small-sized machines to be installed.

- Note) Models with a "W" in its model name belong to the twin-shaft type.

- VPW-*

- VTW-*

- VBW-*

-

Equipped with a displacement sensor compatible with a displacement checker (DPM-01A) that can evaluate the thickness of an object to be welded against the upper and lower limit settings in each welding process and monitor the displacement amount before and after welding.

- ◆Model equipped with a force sensor (P-unit)

Equipped with a P-unit compatible with a AMADA MIYACHI force checker (HCP series) that obtains in each welding process the digital-value measurement for a weld force required for resistance welding and evaluates the weld force. This type can be mounted as an add-on because the force adjustment knob of the force follow-up mechanism can be replaced by itself (Some models are excluded).

- ◆Compatibility

A displacement sensor and a force sensor (P-unit) can be simultaneously mounted in the follow-up mechanism.

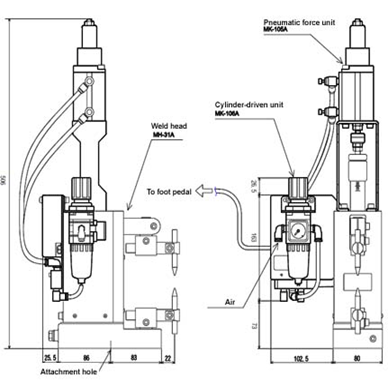

MK-105A

- ◆Pneumatic unit dedicated for MH-21AC and MH-31AC.

- ◆Easy configuration and control of air pressure since it can be built in a weld head.

- ◆Easy adjustment of electrode stroke.

- ◆Stopper controls to apply weld force properly all the time.

MK-106A

- ◆Cylinder driven unit dedicated for MK-105A.

- ◆Five kinds of solenoid-valve-driven voltage: 100VAC, 110VAC, 200VAC, 220VAC, and 2VDC.

- ◆Solenoid valve with security circuit for surge voltage.

- ◆Force follow-up mechanism

Model Force range Electrode holder Dia. of electrode (mm) P-unit Single axis model VP-SS 0.49 - 6.86N Eccentric type φ3 - VPW-S 5 - 120N Eccentric type φ3/φ5/φ8 ✓ VPDW-S *1 VPW-M 40 - 600N Eccentric type φ5/φ8 ✓ VPDW-M *1 Balanced dual axes model VBW-S 5 - 120N *2 Parallel movement type

(When the electrode diameter is φ3 mm: pitch between the electrodes is 3-9 mm)

(When the electrode diameter is φ5 mm: pitch between the electrodes is 5-8.5 mm)φ3/φ5 ✓ Independent dual axes model VT-SS 0.49 - 6.86N Eccentric type □3.2 - VTW-S 5 - 120N Parallel movement type

(when the electrode diameter is φ3 mm: pitch between the electrodes is 3-9 mm)

(when the electrode diameter is φ5 mm: pitch between the electrodes is 5-8.5 mm)φ3/φ5 ✓ VTDW-S *1 VTW-M 40 - 600N Parallel movement type

(when the electrode diameter is φ5 mm: pitch between the electrodes is 6-18 mm)φ5 ✓ VTDW-M *1 - *1. Displacement sensor for MM-370B weld checker can be attached to V□DW-□.

- *2. Applied force of each point will be halved.

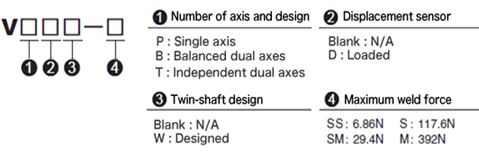

- ◆Model name description

- ◆MK-105A

Model MK-105 Supplied fluid Air Supplied pressure 0.35 to 0.5MPa (3.57 to 5.10kgf / cm2) Ambient temperature 5 to 40°C (No condensation) Adjustment of electrode stroke Stopper / 0 to 20mm Speed adjustment Speed controller - ◆MK-106A

Model MK-106A-00 MK-106A-01 MK-106A-02 MK-106A-03 MK-106A-09 Supplied fluid Air Supplied pressure 0.35 to 0.5MPa (3.57 to 5.10kgf / cm2) Force adjustment Filter regulator Ambient temperature 5 to 40°C (No condensation) Drive voltage of solenoid valve 100VAC 110VAC 200VAC 220VAC 24VDC

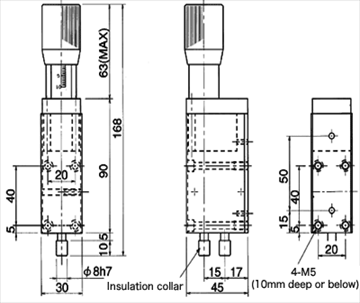

- ◆VPW-S

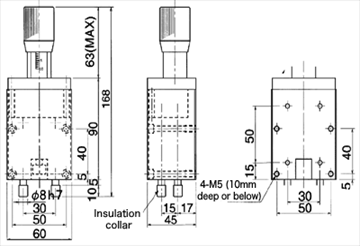

- ◆VTW-S

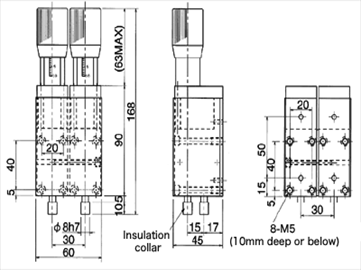

- ◆VBW-S

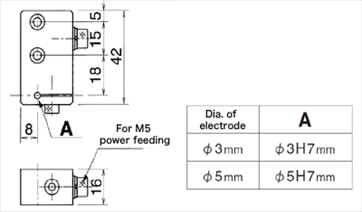

- ◆Eccentric type electrode holder for VPW-S

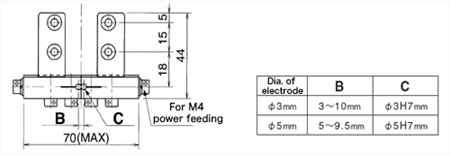

- ◆Parallel moving type electrode holder for VTW-S/VBW-S

- ◆MK-105A/MK-106A