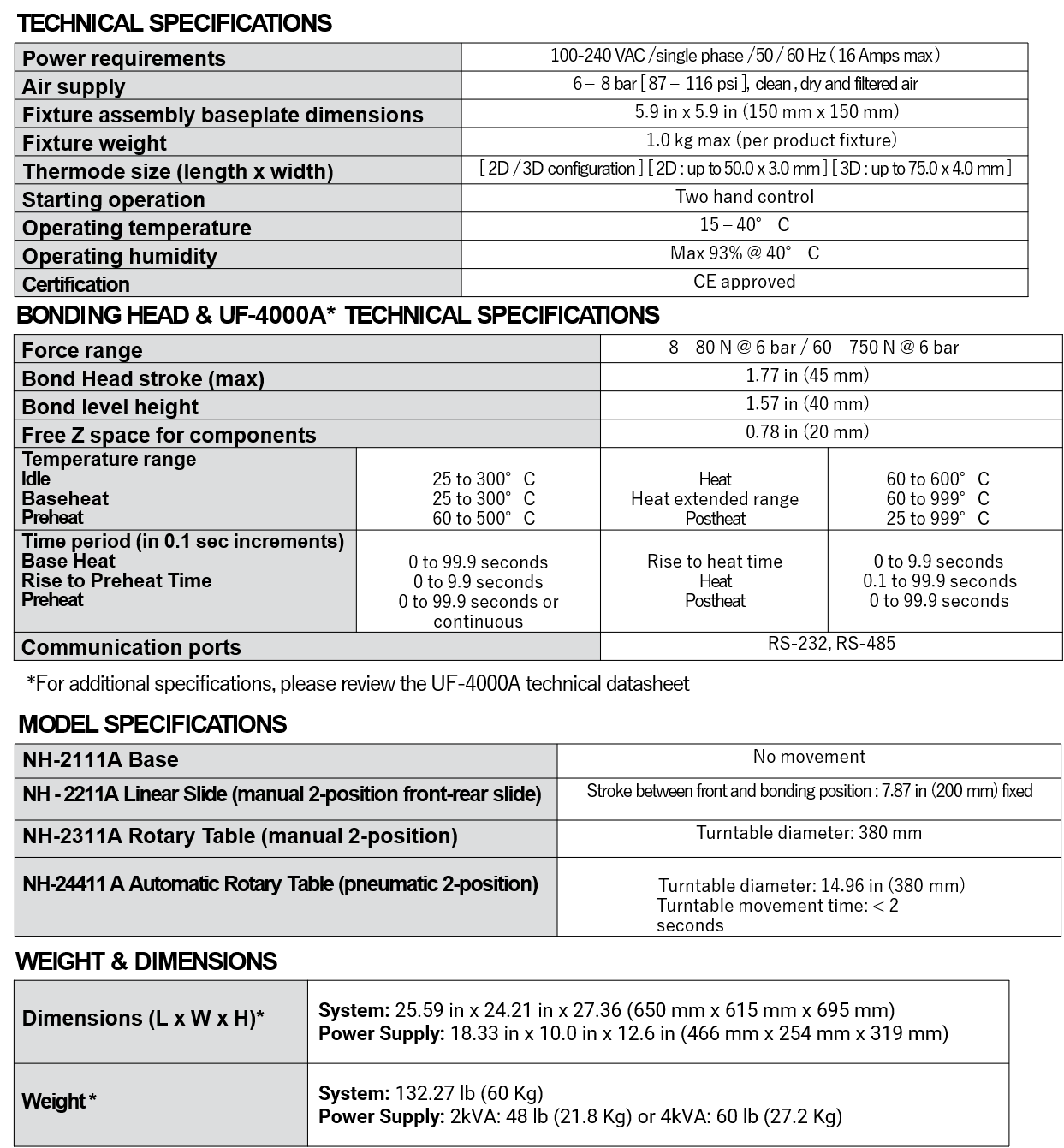

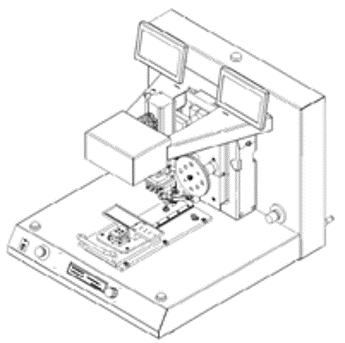

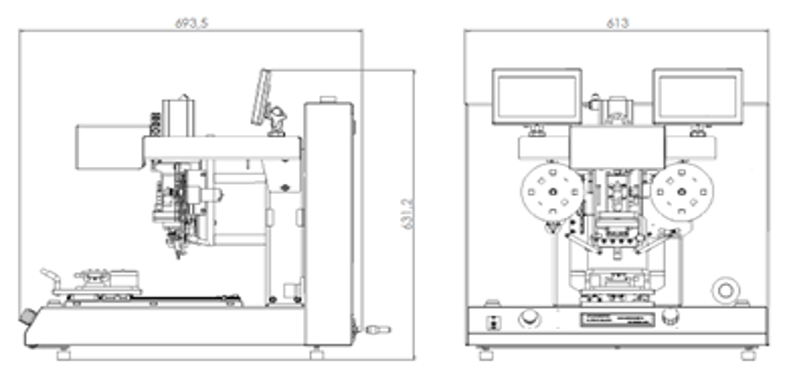

Pulsed Heat Reflow Soldering System

[NH-2000A]

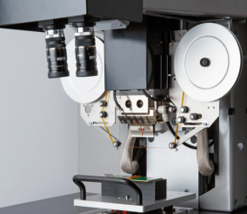

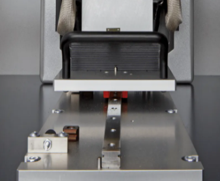

The NH Series Hot Bar Reflow Soldering Systems feature pulsed heat technology, a pneumatic bonding head

and customized 2D and 3D thermodes.Designed to the highest ergonomic standards,

product handling features include either a linear slide or rotary table for optimum production throughput.

Systems can be customized with optional plug & play modules including tape interposers and vision systems mounted on a robust frame.

▶ Key Features

- ◆Compact, flexible standard systems

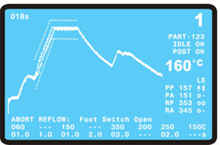

◆UF-4000A Pulsed Heat Power Supply formerly known as Uniflow, Uniflow4, MR-130B

-

-

Displays both graphic and numerical data of setup values, measured values,

waveforms, a schedule number and a program name all at once on a same screen. -

-

◆X-Y thermode planarity adjustment

◆Electronic system control

◆Digital bond force readout

◆Active integrated cooling

◆CE a pproved

◆User-friendly system configuration with optional plug & play modules as below -

▶ Camera Module

The easiest way to align parts to each other is to use pins in the fixture that slide

into reference point.

-

-

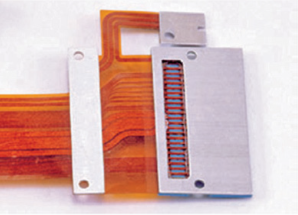

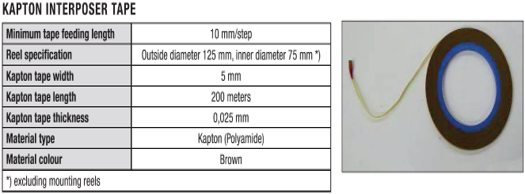

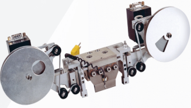

▶ Kapton Interposer Module

The interposer module is a reel-to-reel feeding module using a left and right

sub-module which makes it independent of the Hot Bar length.

Why use Kapton interposer tape? It lengthens the life of the thermode by

protecting it from damage and contamination from repeated exposure to fluxes, and solder.

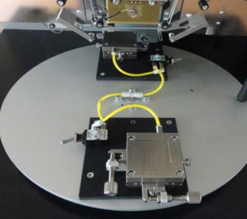

▶ Different of MODEL SPECIFICATIONS

Linear Slide ( 2-position front-rear slide) / Rotary Table ( 2-position )

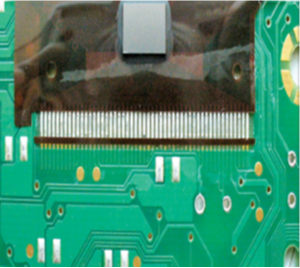

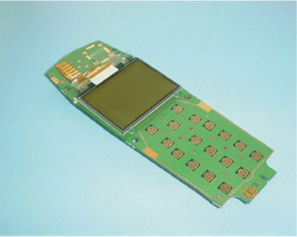

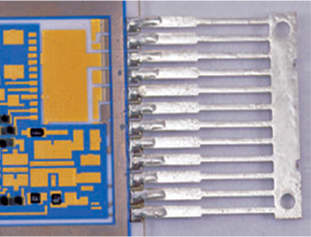

▶ Applications

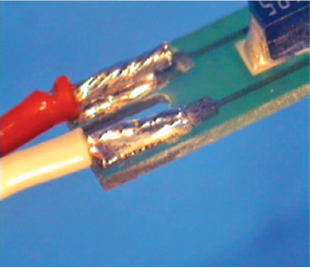

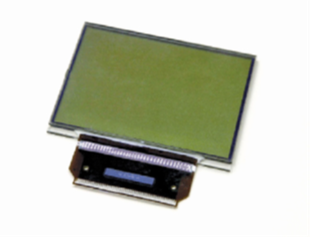

Flex soldering Lead frame to substrate pads

Flex bonding Wire soldering

Open-windowed flex attachment Flex to LCD