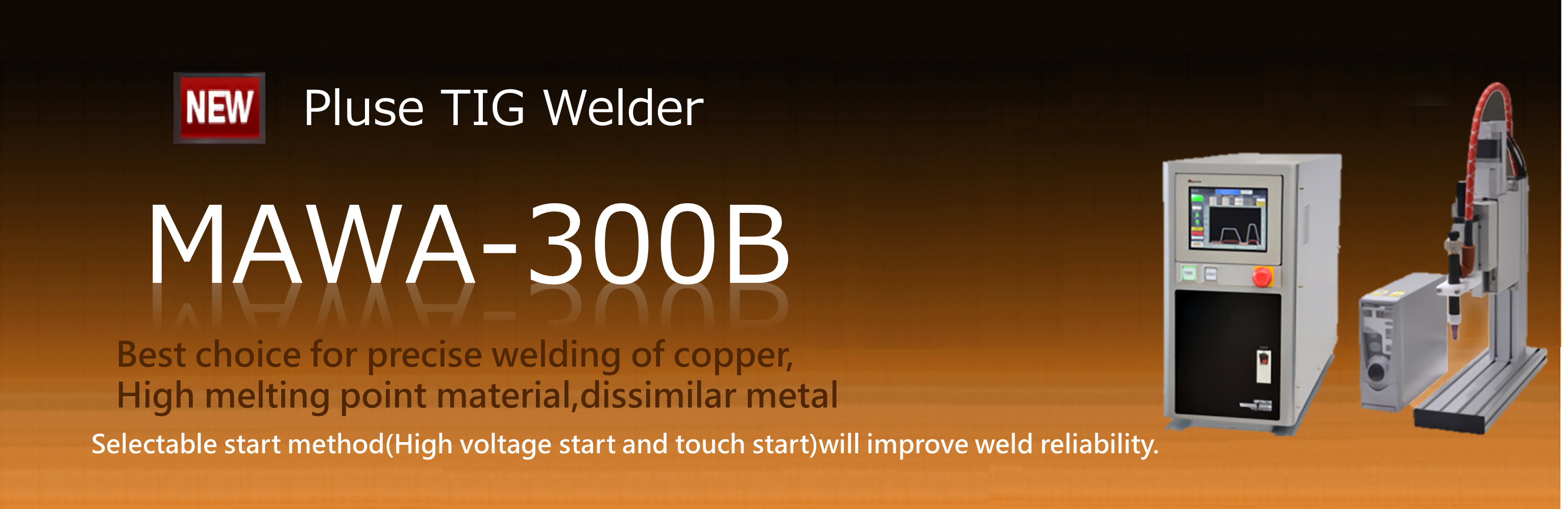

MR-130B

[MR-130B]

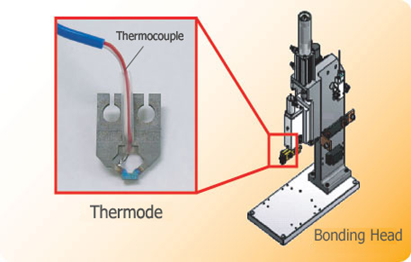

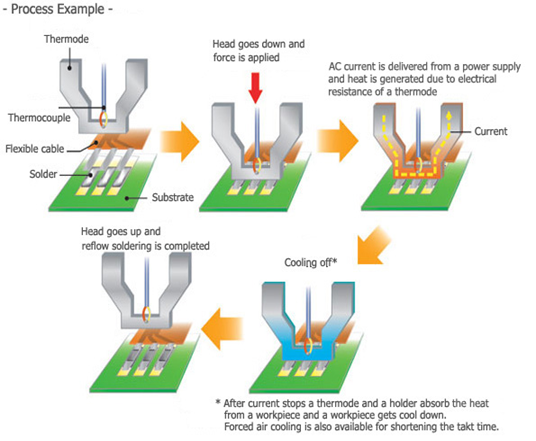

MR-130B pulsed heat controller controls pulsed current for heating to obtain ideal temperature to perform reflow soldering precisely. Real-time temperature feedback from a thermocouple attached to a thermode enables to adjust heat temperature in detail and precision performance according to the programmed heat profile can be done. MR-130B shows great performance also at ACF bonding and heat staking.

[MR-130B]

MR-130B contributes to small footprint due to transformer integrated control unit.

MR-140A is the recommended model, which transformer is placed separately, to integrate into automated machine.

- ◆Precision real-time control

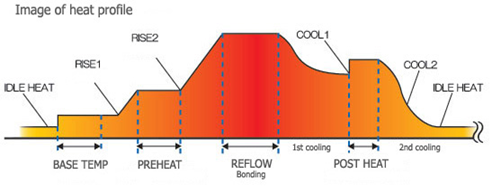

Controls heat temperature utilizing real-time temperature feedback from a thermocouple and heating time to perform in accordance with a

-

◆programmed heat profile.

-

- ◆Large LCD

Displays both graphic and numerical data of setup values, measured values, waveforms, a schedule number and a program name all at once on a same screen.

.png)

- ◆Envelope limits

Displays in waveform both actual temperature and envelope limits at real time and triggers an alarm if the temperature is outside the set envelope limits.

- ◆Data edit keys on the front panel

Allow to edit directly the time and temperature parameters of the heat profile on the graphic display. Those keys are vertically aligned with the profile heating states from Base to Cool2 as displayed on the graphic screen.

.png)

- ◆IDLE HEAT and BASE TEMP

IDLE HEAT is for maintaining the thermode at the Idle Temperature when a process is not active. BASE TEMP is for providing a consistent temperature starting point for the process. These functions make it easier to obtain repeatability and to operate reflow soldering which requires more precise control.

- ◆Auto-switch of voltage

Automatically changes output voltage in accordance with each setup schedule.

- ◆Schedule name registration

Possible to name each schedule with combinations of alphabets and numbers. Helps to distinguish each schedule.

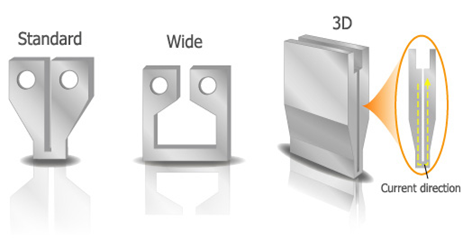

- ◆A variety of thermode lineups

Thermodes which meet customers’ requirements can be offered. Please consult for a design of it.

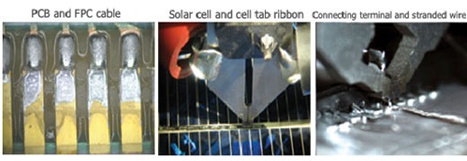

- ◆Applications

| Model | MR-130B | |

| Power requirements | Single phase, 180-264VAC, 50/60Hz | |

| Breaker capacity | 15A | |

| Temperature Control | 600℃ and below | ±6℃ or ±2% of reading, whichever is greater |

| Above 600℃ | ±3% of reading | |

| Repeatability | ±1% of setting | |

| Display Range | 15~999℃ | |

| Temperature range | Base | 25 – 300℃ |

| Preheat | 60 – 500℃ | |

| Reflow | 60 – 999℃ | |

| Cool1 | 25 – 300℃ | |

| Post Heat | 25 – 999℃ | |

| Cool2 | 25 – 300℃ | |

| Idle | 25 – 300℃ | |

|

Time periods |

Base | 0 – 99.9 seconds |

| Rise 1 | 0 – 9.9 seconds | |

| Preheat | 0 – 99.9 seconds | |

| Rise 2 | 0 – 9.9 seconds | |

| Reflow | 0.1 – 99.9 seconds | |

| Post Heat | 0 – 99.9 seconds | |

|

Heating rate capability |

coarse heating rate | Fast / Medium / Slow / Very Slow |

| Fine heating rate | 0 – 99% | |

| Secondary voltage | Fast: 3.81V / Medium: 1.90V / Slow: 1.27V / Very Slow: 0.95V | |

| Cooling method | Air cooling | |

| Schedule programming * | Front panel or external controller via RS-232C/RS-485C | |

| RS-232/RS-485 Connectors | Standard 9 Pin D-Sub female connector | |

| User Programmable Heat Profiles | 63 | |

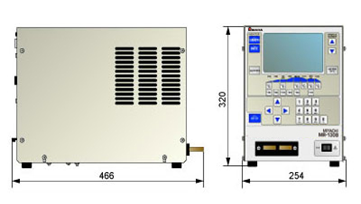

| Dimensions (mm) | 254(W) x 466(D) x 320(H) | |

| Mass | 27kg | |

| Ambient temperature / humidity | 15 – 40℃ / 93% (40℃) No condensation | |

*External controller will be prepared by customers.

◆MR-130B