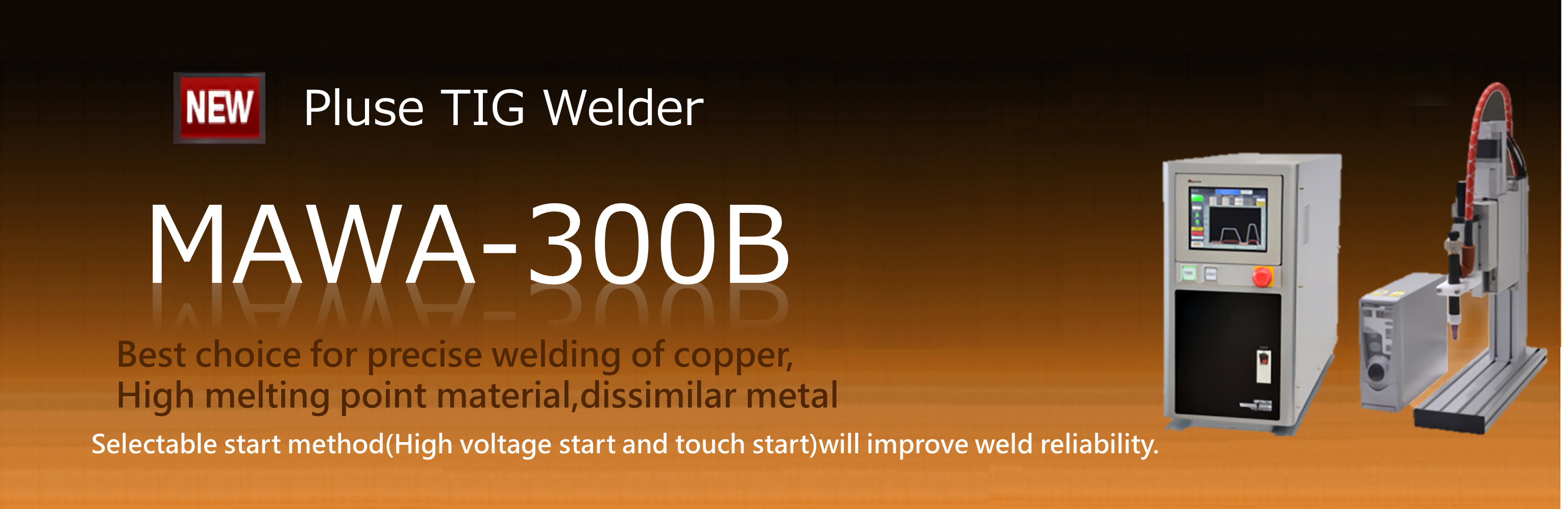

【NEW】ML-3000series

Adopt a new air cooling system and pulse fiber laser system. Compared with YAG laser excitation of the lamp the conventional method, and realization high-quality, significant low power consumption, low running costs and more!

In addition to the fine pulse welding, high speed CW (continuous wave) welding is possible, it supports a variety of applications. It is most suitable for the replacement of a YAG laser.

Be superior to laser oscillation efficiency, this model will contribute to the manufacturing of environmentally conscious energy-saving, low-cost

▶ Features

◆This welder employs a full air-cooling system, which does not use a chiller, thereby reducing operating costs

◆Power consumption of the pulse fiber laser is approx. 85% less than that of Nd:YAG lasers (ML-3060A/AS)

◆With its large energy of 60 J this pulse fiber laser welder can be used for the type of welding that was previously only achieved by Nd:YAG lasers (ML-3060A/AS)

◆The product lineup includes the 300 W ML-3030AS and the 150 W ML-3015AS in the same size body.

◆With a large output of up to 600 W, this pulse fiber laser welder can be used for high speed seam sealing

◆Stable output power with real-time power feedback

◆Consistent spot size without thermal lens effects

◆Pulse and CW (continuous wave oscillation) operations are available

◆Intuitive large color LCD touch screen panel (no PC necessary to configure settings or check operating state)

◆Built-in power monitor

◆ML-3060A/AS: Up to 4 time-sharing fiber deliveries are available. (When the isolator Option is mounted, Up to 3 time-sharing fiber deliveries are possible)

*ML-3030AS/3015AS: Provide 2 laser output deliveries via either time-sharing or energy sharing.

The isolation function (Option) protects the oscillator from light reflected from the processing point.

* When the optional isolator is mounted, the laser power output from the fiber decreases by up to 10%.

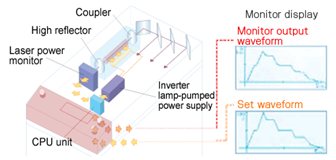

▶ Real-time power feedback

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

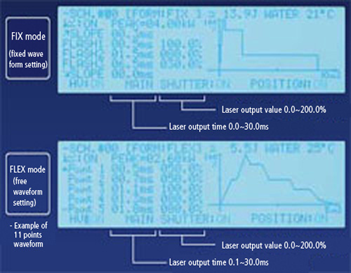

▶ Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

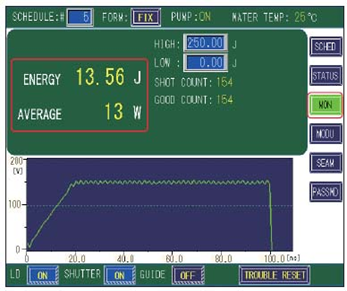

▶ Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

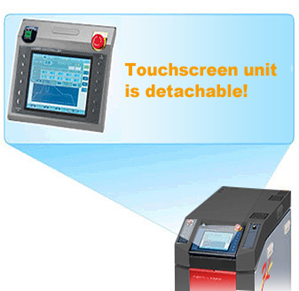

▶ Color LCD touch panel

The touch panel can be detached from the main unit and operated by hand.

▶ External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

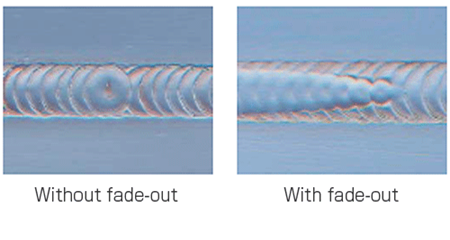

▶ Fade-in/Fade-out

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

| Model | ML-3060A | ML-3060AS | ML-3030AS | ML-3015AS |

| Maximum average power (oscillator output)* |

REPEAT mode 600W / CW mode 550 W | REPEAT mode 300W / CW mode 270 W | REPEAT mode 150W / CW mode 135 W | |

| Maximum peak power (oscillator output)* |

REPEAT mode 5.5kW / CW mode 0.55kW | REPEAT mode 2.7kW / CW mode 0.27kW | REPEAT mode 1.35kW / CW mode 0.135kW | |

| Pulse width | 0.2 to 50.00 ms (0.05ms steps) | |||

| Repeated number of pulse | 1 to 1000 pps (REPEAT mode) | |||

| Modulation function | 1–5000 Hz (rectangular wave, triangular wave, sinusoidal wave) (CW mode) | |||

| Oscillation wavelength | 1070nm±3nm | |||

| Positioning guide beam | Built-in visible laser (Red) | |||

| Prevention of reflected beam | Built-in reflected beam sensor | |||

| P.F. fiber | SI-0.3/0.4/0.6/0.8 (NA0.20) | SI-0.1 (NA0.20) | SI-0.1/0.2/0.3/0.4/0.6/0.8 (NA0.20) | |

| Fiber optic delivery | Up to 4 time-sharing fiber deliveries are available.(Option) (When the isolator (option) is mounted, Up to 3 time-sharing fiber deliveries) | Up to 2 deliveries of laser output,including powersharing andtimesharing, are available. (Option) | ||

| No. of programmable schedules | 256 | |||

| Measurement function | Laser energy (J), Average power (W) | |||

| Counter | Displays the total number of outputs (9 digits)/Displays the number of acceptable outputs (9 digits)/Displays the total LD ON time (7 digits)/Displays the laser output time (7 digits) | |||

| Power supply | Single-phase, 200 V to 240 V AC (+10%/-15%) 50/60Hz | |||

| Max. input current | 23A(200V), 21A(220V), 19A(240V) | 11A(200V), 10A(220V), 9A(240V) | 9A(200V), 8.2A(220V), 7.5A(240V) | |

| Power consumption | 3.5kW at max. (0.2kW while stand-by) | 2.0kW at max. (0.2kW while stand-by) | 1.6kW at max. (0.2kW while stand-by) | |

| Breaker rated current | 30A | 15A | ||

| External datacom | RS-485 | |||

| Cooling method | Forced air-cooled | |||

| Ambient temperature | 10 to 35°C | |||

| Ambient humidity | 50% to 85% RH (where there is no sudden moisture) | |||

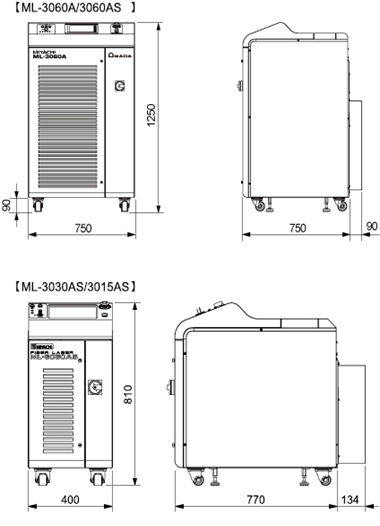

| Dimensions | 750(W)×750(D)×1250(H)mm | 400(W)×770(D)×810(H)mm | ||

| Weight | 250kg or less | 150kg or less | ||

* When the optional isolator is mounted, the laser power output from the fiber decreases by up to 10%.

*Specifications subject to change without notice

▶ Dimensions in mm

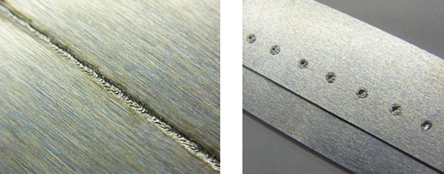

◢ High-quality spot welding and seam welding of aluminum

◢ High-quality spot welding of SUS 304

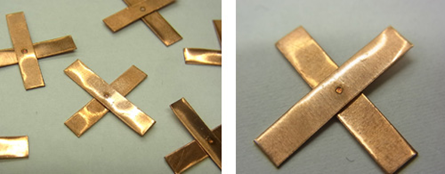

◢ Spot welding of copper materials