ML-2550A.ML-2551A.ML-2552A.ML-2650B.ML-2651B

- Home

- Products

- Laser Welders

- YAG Laser Welder

- ML-2550A.ML-2551A.ML-2552A.ML-2650B.ML-2651B

◆Welding with a few heat-affected area can be done due to that laser welding is "contactless" welding.

◆Real-time Power Feedback feature ensures stable welding under optimum weld conditions.

◆Employing an optical fiber makes its automation easy.

◆High power oscillator enables high speed seam welding.

◆Up to four energy sharing.

◆Controller is detachable.

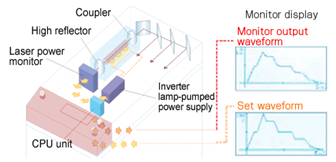

▶ Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

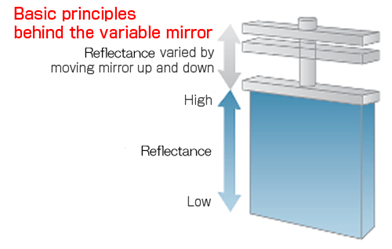

▶ Variable mirrors

These mirrors eliminate laser power loss and improve branch balance.

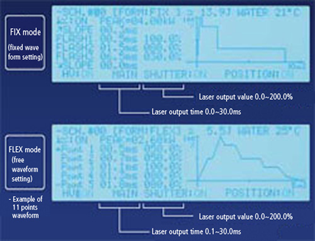

▶ Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

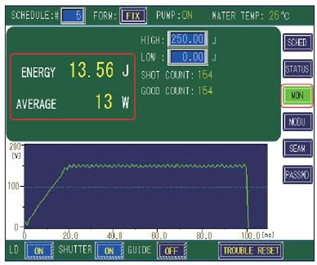

▶ Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

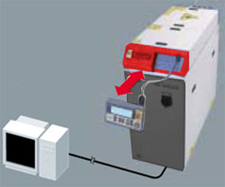

▶ Controller

The controller can be detached from the main unit to operate at your hand.

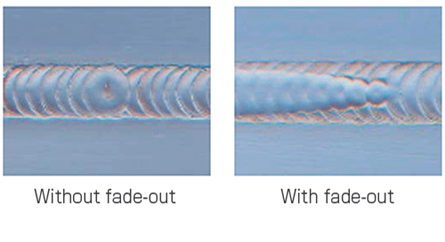

This feature avoids marks at the end of seam welding and provides a beautiful finish even for overlapping circumference seam welding sections.

| Model | ML-2550A | ML-2551A | ML-2552A | ML-2650B | ML-2651B | |

|---|---|---|---|---|---|---|

| Oscillation wavelength | 1064nm | |||||

| Maximum average power | 400W | 300W | 300W*1 | 600W | 500W | |

| Maximum output energy | 80 J/P (Pulse width 10ms) | 50 J/P (Pulse width 10ms) | 20 J/P (Pulse width 4ms) | 100 J/P (Pulse width 10ms) | 80 J/P (Pulse width 10ms) | |

| Pulse width | Standard: 0.3 to 100.0 ms (0.1 ms steps) | |||||

| Fine setting: 0.25 to 5.00 ms (0.05 ms steps) | ||||||

| Pulse repetition | 1 to 500pps | |||||

| Fiber optic delivery | Up to 4 deliveries of laser output are available including powersharing and timesharing. (optional) | |||||

| External datacom | RS-485 | |||||

| Power requirements | 3-phase, 200, 240, 380, 400 V AC±10%, 50/60Hz 3-phase, 220 V AC+10%-15%, 50/60Hz(Tap switching) |

|||||

| Cooler | Heat exchange method | Water - Water | ||||

| Required city water | Pressure: 294kPa (3kgf/cm²) maximum | |||||

| Water temperature: 5° to 35°C | ||||||

| Flow rate: 16 litter/min at 30°C 25 litter/min at 35°C |

Flow rate: 25 litter/min at 25°C 55 litter/min at 32°C |

|||||

| Differential pressure: 98 to 294kPa (1 to 3kgf/cm²) | ||||||

| Inner diameter of hose | Φ15mm | Φ19mm | ||||

| When chiller is employed, cooling capability of 11.8 kW (10150kcal/h) is required for the chiller cooler | When chiller is employed, cooling capability of 23.5kW(20160 kcal/h) is required for the chiller cooler maximum | |||||

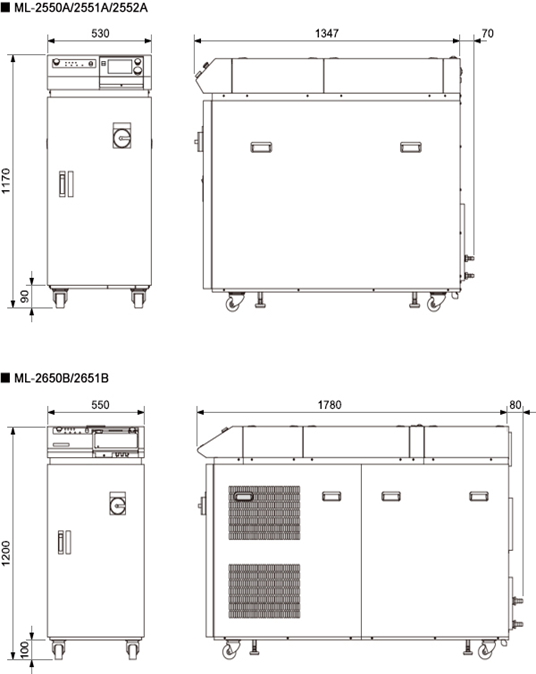

| Dimensions | 530(W) X 1,347(D) X 1,170(H)mm | 550(W) X 1,780(D) X 1,200(H)mm | ||||

| Weight | Approx. 400 kg (at 220, 240 V AC), Approx. 450 kg (at 380 V AC) |

540kg | ||||

- *1: Value in case of when pulse width is set between 0.8 and 15.0ms and when peak power is over 1.5W. When it is not under this condition, maximum power is 250W.

Specifications subject to change without notice.

▶ Dimensions in mm

|

|

|

| Cigarette lighter | Gimbals | Optic connector |

|

|

|

| Motor core | Transformer core | Transformer core |

|

|

|

|

| Titanous body | Discharge valve | Motor | Lithium-ion battery |